HACCP is a management system in which food safety is addressed through the analysis and control of biological, chemical, and physical hazards from raw material production, procurement and handling, to manufacturing, distribution and consumption of the finished product.

Food Safety Management Plan

Onboard seagoing vessels, the Chief Cook is responsible for ensuring all galley and catering staff complies with the Food Safety Management Plan which should be followed as per Owner’s or Manager’s instructions.

This plan covers required procedures for safe food management and provides guidelines, forms and checklists.

The Food Safety Management Plan should be based on the below HACCP principles.

HACCP Principles

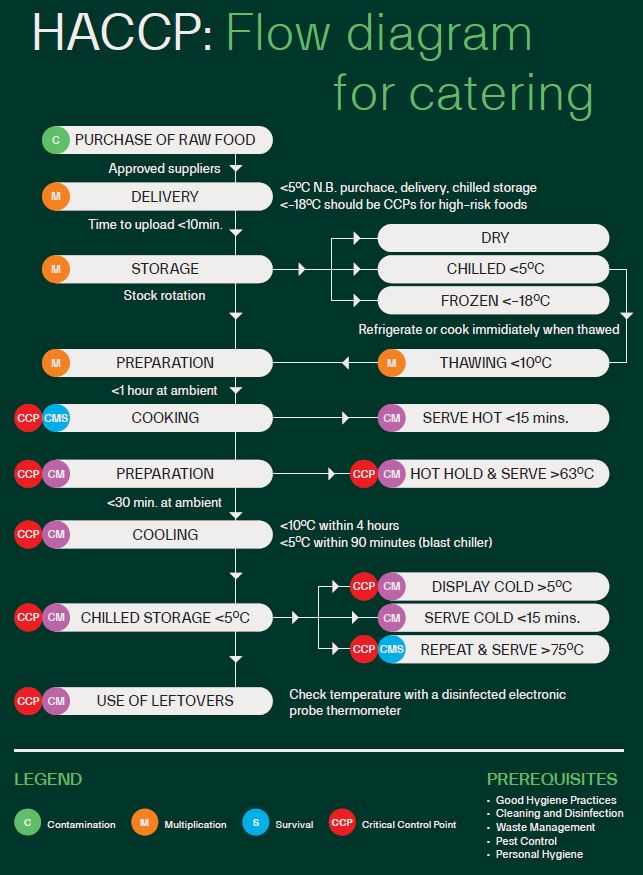

A HACCP system is used to control risks and hazards throughout the flow of food. HACCP is based on identifying significant biological, chemical, or physical hazards at specific points within a product’s flow. Once identified, the hazards can be prevented, eliminated, or reduced to safe levels.

An effective HACCP system must be based on a written plan. This plan must be specific to each facility’s menu, customers, equipment, processes, and operations. Since each HACCP plan is unique, a plan that works for one operation may not work for another.

The HACCP Approach

A HACCP plan is based on seven basic principles. They were created by the National Advisory Committee on Microbiological Criteria for Foods. These principles are the seven steps that outline how to create a HACCP plan.

The Seven HACCP Principles

Each HACCP principle builds on the information gained from the previous principle. You must consider all seven principles in order, when developing your plan.

Here are the seven principles:

- Conduct a hazard analysis.

- Determine critical control points (CCPs)

- Establish critical limits.

- Establish monitoring procedures.

- Identify corrective actions.

- Verify that the system works.

- Establish procedures for record keeping and documentation

In general terms, the principles break into three groups.

- Principles 1 and 2 help you identify and evaluate your hazards.

- Principles 3, 4 and 5 help you establish ways for controlling those hazards.

- Principles 6 and 7 help you maintain the HACCP plan and system, and verify its effectiveness.

PRINCIPLE 1: CONDUCT A HAZARD ANALYSIS

First, identify and assess potential hazards in the food you serve. Start by looking at how food is processed in your operation.

Many types of food are processed in similar ways. Here are some common processes.

- Prepping and serving without cooking (salads, cold sandwiches, etc.)

- Prepping and cooking for same_day service (grilled chicken sandwiches, hamburgers, etc.)

- Prepping, cooking, holding, cooling, reheating, and serving (chilli, soup, pasta sauce with meat, etc.)

Look at your menu and identify items that are processed like this. Next, identify the TCS food.

Determine where food safety hazards are likely to occur for each TCS food.

These types of hazards as discussed earlier can be a) Biological, b) Chemical & c) Physical.

PRINCIPLE 2: DETERMINE CRITICAL CONTROL POINTS (CCPS)

Find the points in the process where the identified hazard(s) can be prevented, eliminated, or reduced to safe levels.

These are the critical control points (CCPs). Depending on the process, there may be more than one CCP.

PRINCIPLE 3: ESTABLISH CRITICAL LIMITS

For each CCP, establish minimum or maximum limits. These limits must prevent or eliminate the hazard, or to reduce it to a safe level.

PRINCIPLE 4: ESTABLISH MONITORING PROCEDURES

Once critical limits have been created, determine the best way for your operation to check them.

Make sure the limits are consistently met. Identify who will monitor them and how often.

PRINCIPAL 5: IDENTIFY CORRECTIVE ACTIONS

Identify steps that must be taken when a critical limit is not met. These steps should be determined in advance.

PRINCIPLE 6: VERIFY THAT THE SYSTEM WORKS

Determine if the plan is working as intended. Evaluate it on a regular basis. Use your monitoring charts, records, hazard analysis, etc., and determine if your plan prevents, reduces, or eliminates identified hazards.

PRINCIPLE 7: ESTABLISH PROCEDURES FOR RECORD KEEPING AND DOCUMENTATION

Maintain your HACCP plan and keep all documentation created when developing it. Keep records for the following actions:

- Monitoring activities

- Taking corrective action

- Validating equipment (checking for good working condition)

- Working with suppliers (e.g., shelf_life studies, invoices, specifications, challenge studies, etc.)

Source: OCEANIC MAGAZINE (Oct 2023)