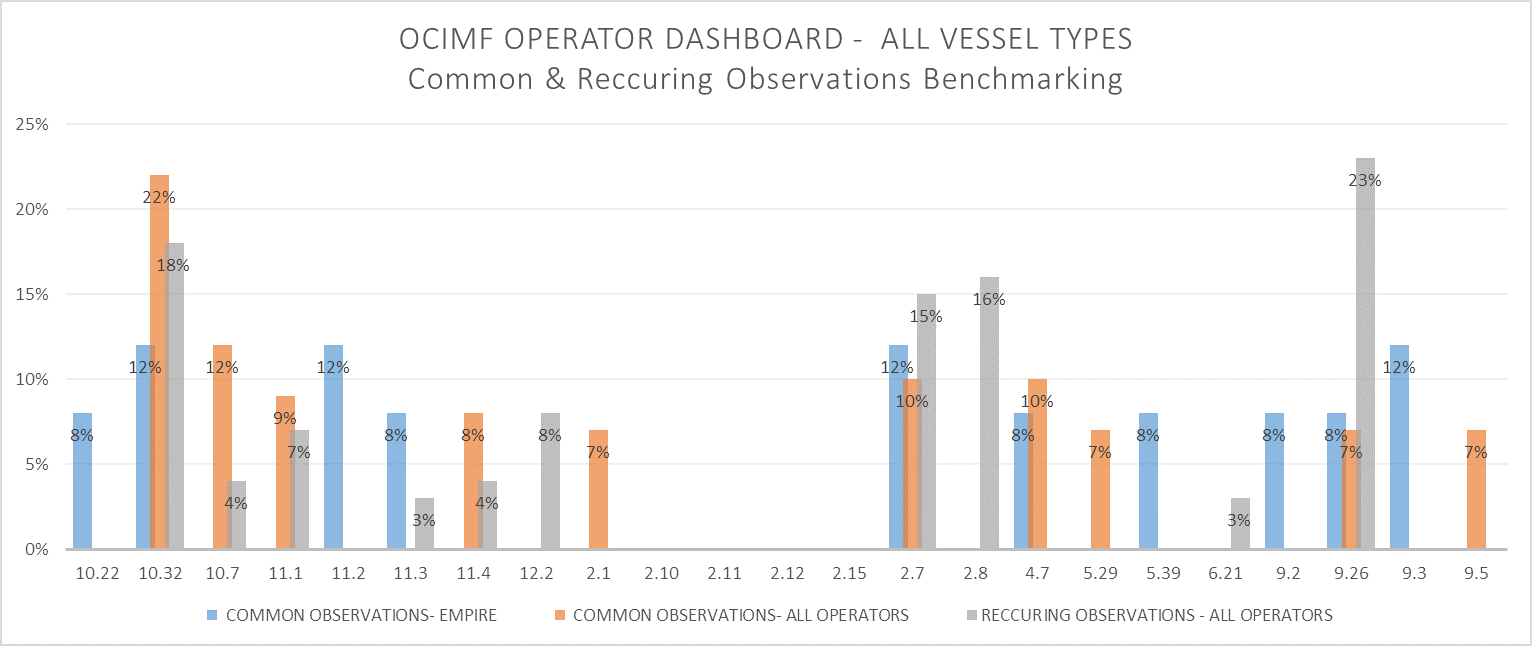

Following graphs provide a benchmarking overview of SIRE inspections performance based on OCIMF Data mining data provided in OCIMF website for the reporting period.

All Tankers - YT2Q20

From the begining of the year till the end of 2Q20 the following most common observation have been raised to our managed fleet (all types) in comparison to the ones raised in all operatiors. Table also presents the re-current elements in all SIRE inspections:

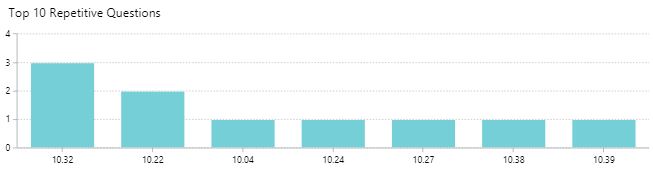

| QUESTION CODE | DESCRIPTION | COMMON OBSERVATIONS- EMPIRE FLEET | COMMON OBSERVATIONS- ALL OPERATORS | RECCURING OBSERVATIONS - ALL OPERATORS |

| 10.22 | Where hydraulic aggregate pumps are located within the main engine compartment, is an oil mist detector fitted? | 8% | ||

| 10.32 | Are the following, where applicable, all in good order and do they appear to be well maintained? | 12% | 22% | 18% |

| 10.7 | Does the operator subscribe to a fuel, lube and hydraulic oil testing programme on a frequency in accordance with the manufacturers recommendations and are there procedures to act on these results? | 12% | 4% | |

| 11.1 | Is the general condition, visual appearance and cleanliness of the hull satisfactory. | 9% | 7% | |

| 11.2 | Are hull markings clearly indicated and correctly placed? | 12% | ||

| 11.3 | Is the general condition, visual appearance and cleanliness of the weather decks satisfactory and are deck working areas clearly identified and provided with non-slip surfaces? | 8% | 3% | |

| 11.4 | Is the general condition of service pipework satisfactory and is it free from significant corrosion and pitting and soft patches or other temporary repairs? | 8% | 4% | |

| 12.2 | Are means in place to detect ice? | 8% | ||

| 2.1 | Are all the statutory certificates listed below, where applicable, valid and have the annual and intermediate surveys been carried out within the required range dates? | 7% | ||

| 2.7 | Is the vessel free of conditions of class or significant recommendations, memoranda or notations? | 12% | 10% | 15% |

| 2.8 | Has the vessel been enrolled in a Classification Society Condition Assessment programme (CAP)? | 16% | ||

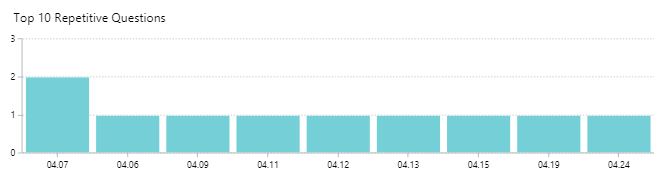

| 4.7 | Is navigation equipment appropriate for the size of the vessel and in good order? | 8% | 10% | |

| 5.29 | Are lifeboats, including their equipment and launching mechanisms, in good order and have they been launched and manoeuvred in the water in accordance with SOLAS requirements? | 7% | ||

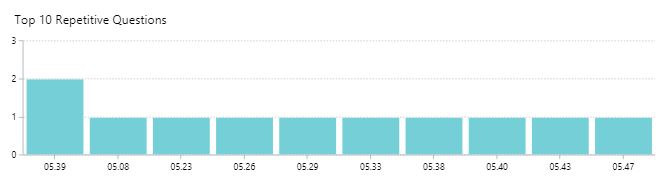

| 5.39 | Are officers aware of the requirements for testing fixed fire detection and alarm systems and are the systems in good order and tested regularly? | 8% | ||

| 6.21 | If the vessel is provided with an approved Ballast Water Treatment System, is the system in good order, used where required and are officer's familiar with the safe operation of the same? | 3% | ||

| 9.2 | Does the ship have a Mooring System Management Plan? | 8% | ||

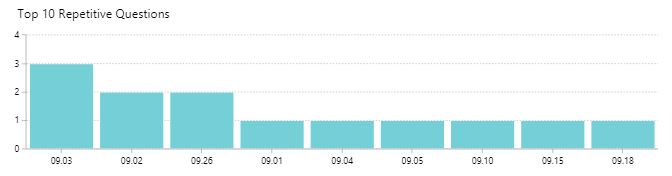

| 9.26 | If the vessel is equipped for mooring at single point moorings, does it meet the recommendations as applicable, contained in Mooring Equipment Guidelines? | 8% | 7% | 23% |

| 9.3 | Does the ship have a Line Management Plan? | 12% | ||

| 9.5 | Do all mooring lines and where fitted, mooring tails, meet Industry guidelines? | 7% |

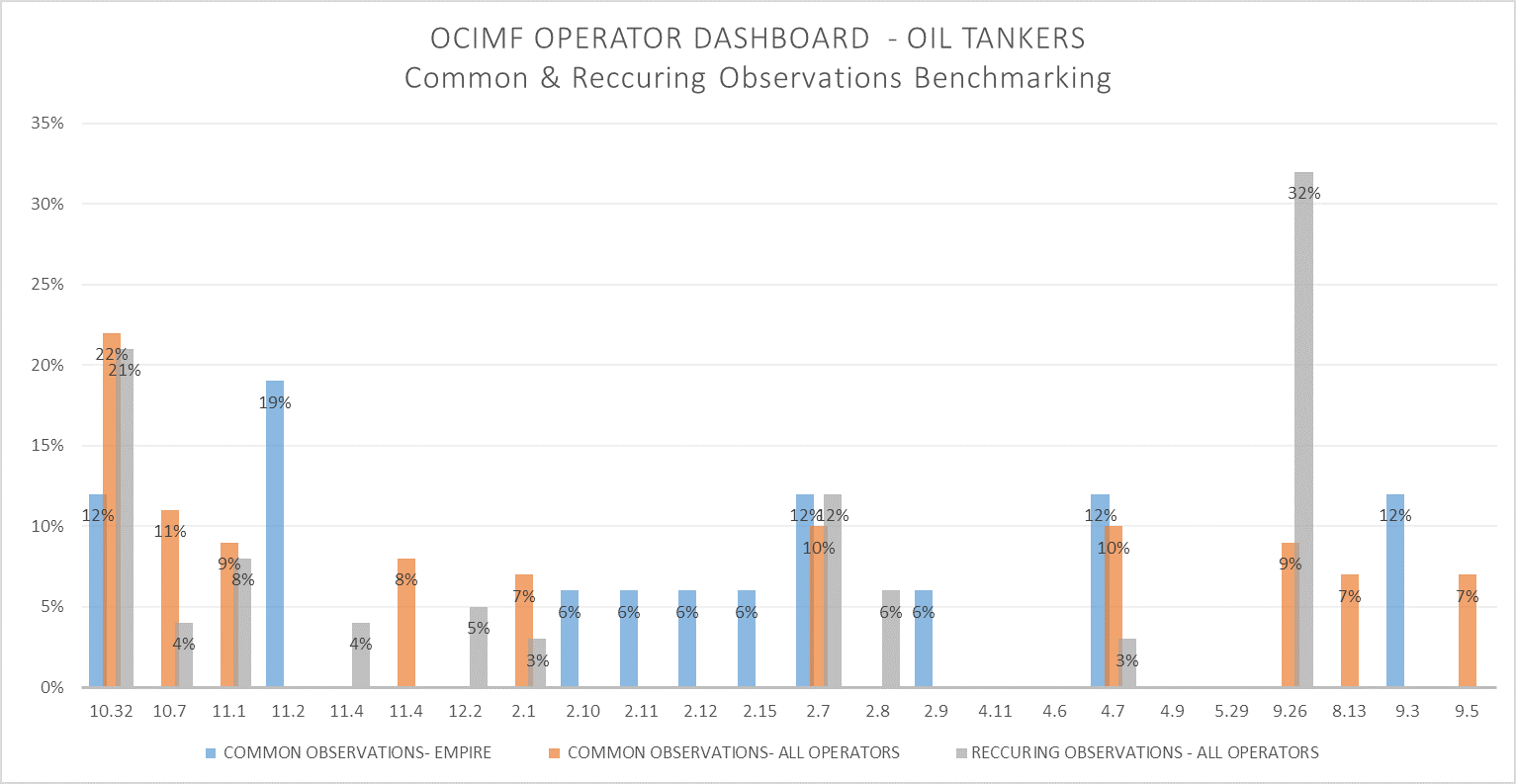

Crude Oil Tankers - YT2Q20

From the begining of the year till the end of 2Q20 the following most common observation have been raised to our Crude Oil Tankers managed by the Company in comparison to similar ones raised in all operatiors. Table also presents the re-current elements in all SIRE inspections:

| QUESTION CODE | DESCRIPTION | COMMON OBSERVATIONS- EMPIRE | COMMON OBSERVATIONS- ALL OPERATORS | RECCURING OBSERVATIONS - ALL OPERATORS |

| 10.32 | Are the following, where applicable, all in good order and do they appear to be well maintained? | 12% | 22% | 21% |

| 10.7 | Are the following, where applicable, all in good order and do they appear to be well maintained? | 11% | 4% | |

| 11.1 | Is the general condition, visual appearance and cleanliness of the hull satisfactory. | 9% | 8% | |

| 11.2 | Are hull markings clearly indicated and correctly placed? | 19% | ||

| 11.4 | Is the general condition of service pipework satisfactory and is it free from significant corrosion and pitting and soft patches or other temporary repairs? | 8% | 4% | |

| 12.2 | Are means in place to detect ice? | 5% | ||

| 2.1 | Are all the statutory certificates listed below, where applicable, valid and have the annual and intermediate surveys been carried out within the required range dates? | 7% | 3% | |

| 2.10 | Are the Engine Room (Part I) and Cargo (Part II) Oil Record Books (ORBs) correctly completed, free of any pollution incidents, violations and are slop/waste oil disposal certificates provided? | 6% | ||

| 2.11 | If the disposal of engine room oily water or sludge to a cargo or slop tank has taken place, has the event been recorded in both Oil Record Books, was the receiving tank free of cargo and have the transfer arrangements been approved as per IOPP Form B? | 6% | ||

| 2.12 | Is the vessel in possession of an approved Volatile Organic Compounds (VOC) Management Plan and the deck officers aware of the general contents and requirements of the plan? | 6% | ||

| 2.15 | Is the vessel free of any documentary or visual evidence to indicate any structural concerns? | 6% | ||

| 2.7 | Is the vessel free of conditions of class or significant recommendations, memoranda or notations? | 12% | 10% | 12% |

| 2.8 | Has the vessel been enrolled in a Classification Society Condition Assessment programme (CAP)? | 6% | ||

| 2.9 | Are procedures in place to carry out regular inspections of cargo and ballast tanks, void spaces, trunks and cofferdams by the vessel's personnel and are records maintained? | 6% | ||

| 4.7 | Is navigation equipment appropriate for the size of the vessel and in good order? | 12% | 10% | 3% |

| 9.26 | If the vessel is equipped for mooring at single point moorings, does it meet the recommendations as applicable, contained in Mooring Equipment Guidelines? | 9% | 32% | |

| 8.13 | Are the remote and local temperature and pressure sensors and gauges in good order and is there recorded evidence of regular testing? | 7% | ||

| 9.3 | Does the ship have a Line Management Plan? | 12% | ||

| 9.5 | Do all mooring lines and where fitted, mooring tails, meet Industry guidelines? | 7% |

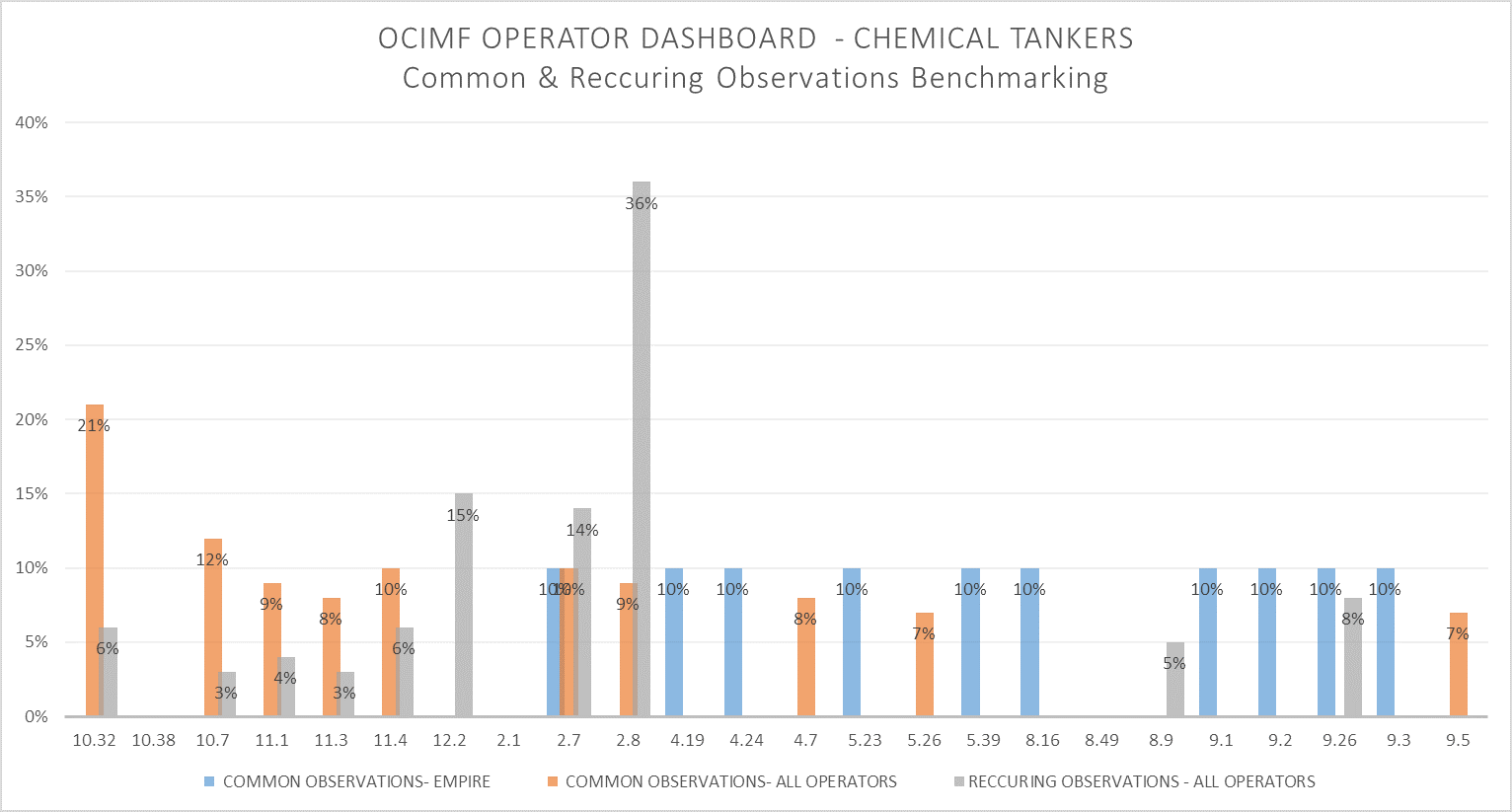

Chemical Tankers - YT2Q20

From the begining of the year till the end of 2Q20 the following most common observation have been raised to our Chemical Tankers managed by the Company in comparison to similar ones raised in all operatiors. Table also presents the re-current elements in all SIRE inspections:

| QUESTION CODE | DESCRIPTION | COMMON OBSERVATIONS- EMPIRE | COMMON OBSERVATIONS- ALL OPERATORS | RECCURING OBSERVATIONS - ALL OPERATORS |

| 10.32 | Are the following, where applicable, all in good order and do they appear to be well maintained? | 21% | 6% | |

| 10.7 | Does the operator subscribe to a fuel, lube and hydraulic oil testing programme on a frequency in accordance with the manufacturers recommendations and are there procedures to act on these results? | 12% | 3% | |

| 11.1 | Is the general condition, visual appearance and cleanliness of the hull satisfactory. | 9% | 4% | |

| 11.3 | Is the general condition, visual appearance and cleanliness of the weather decks satisfactory and are deck working areas clearly identified and provided with non-slip surfaces? | 8% | 3% | |

| 11.4 | Is the general condition of service pipework satisfactory and is it free from significant corrosion and pitting and soft patches or other temporary repairs? | 10% | 6% | |

| 12.2 | Are means in place to detect ice? | 15% | ||

| 2.1 | Are all the statutory certificates listed below, where applicable, valid and have the annual and intermediate surveys been carried out within the required range dates? | |||

| 2.7 | Is the vessel free of conditions of class or significant recommendations, memoranda or notations? | 10% | 10% | 14% |

| 2.8 | Has the vessel been enrolled in a Classification Society Condition Assessment programme (CAP)? | 9% | 36% | |

| 4.19 | Is the master and deck officers aware of the requirements for the echo sounder and is there evidence that it has been in use as appropriate during the voyage? | 10% | ||

| 4.24 | Is there a maintenance programme in place to ensure availability of the radio equipment? | 10% | ||

| 4.7 | Is navigation equipment appropriate for the size of the vessel and in good order? | 8% | ||

| 5.23 | Does the vessel have appropriate duplicate portable gas detection equipment suitable for the cargoes carried, are the officers' familiar with the operation, calibration and is the equipment being maintained in accordance with manufacturers and industry recommendations? | 10% | ||

| 5.26 | Is gas welding and burning equipment in good order and spare oxygen and acetylene cylinders stored apart in a well-ventilated location outside of the accommodation and engine room? | 7% | ||

| 5.39 | Are officers aware of the requirements for testing fixed fire detection and alarm systems and are the systems in good order and tested regularly? | 10% | ||

| 8.16 | If the vessel provided with wall wash test equipment, are the officers familiar with the wall wash test procedures and are the procedures comprehensive and consider the safety aspects of the process? | 10% | ||

| 8.9 | Is the vessel free of inherent intact stability problems, are officers aware of these problems or risks of structural damage from sloshing, and actions required if the vessel takes on an unstable condition and/or angle of loll? | 5% | ||

| 9.1 | Are certificates available for all mooring lines and wires? | 10% | ||

| 9.2 | Does the ship have a Mooring System Management Plan? | 10% | ||

| 9.26 | If the vessel is equipped for mooring at single point moorings, does it meet the recommendations as applicable, contained in Mooring Equipment Guidelines? | 10% | 8% | |

| 9.3 | Does the ship have a Line Management Plan? | 10% | ||

| 9.5 | Do all mooring lines and where fitted, mooring tails, meet Industry guidelines? | 7% |

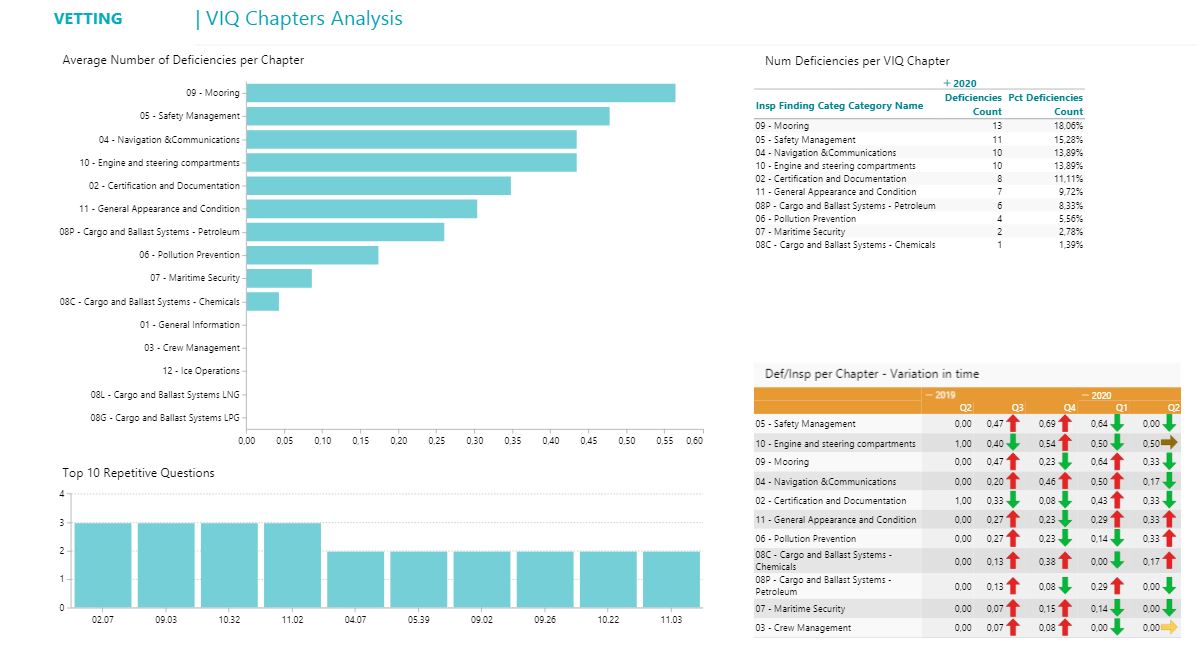

Summarizing, in reporting period, the Chapters with the highest number of findings are 09-Mooring, 05-Safety Management, 04-Navigation and Coommunication, 10-Engine and Steering Compartments and 02-Certification Documentation as seen in below charts:

However if you look upon the variation in time graph below, in Q1 and Q2 we have seen a significant drop in findings/Inspection ratio for Chapter 05-Safety Management, and in Q2 we have seen same decline for Chapters 04-Navigation and Coommunication, 09-Mooring & 02-Certification Documentation. Chapters 0-Engine and Steering Compartments, 06-Pollution prevention and 08C-Cargo and Ballast Systems (Chemical Tankers) have shown some slight increase and need to be closely monitored.

It is worth looking on the top 4 Chapters with more more findings and focus on the questions that relate to the most findings raised

Ch. 9 Mooring - Top 10 Questions with findings

Ch.10 Safety Management - Top 10 Questions with findings

Ch. 4 Navigation and Communication - Top 10 Questions with findings

Ch. 10 Engine and Steering Compartment - Top 10 Questions with findings

Source: Z. Lempesi / HSQE Manager